What is Supplier Evaluation?

Supplier evaluation is a formal assessment of suppliers based on a standardised set of evaluation criteria to select the best-suited vendors. Organisations perform supplier evaluations to qualify potential suppliers and assess existing relationships, recognising that such assessments are crucial to remain competitive.

Procurement teams are tasked with optimising budget spend, making supplier evaluation essential for securing contracts from vendors who offer optimal quality, cost-effectiveness and reliability.

Benefits of Supplier Evaluation

Although the supplier assessment process can be tedious and time consuming, there are several benefits of supplier evaluation that will positively impact your business operations.

- Improved Supplier Performance

Suppliers are essential to any business, and therefore having high performing suppliers is paramount. Standardised evaluation processes empower organisations to effectively identify vendors who best align with their business requirements, fostering a more harmonious match between supplier capabilities and organisational needs. By encouraging impartial assessment and deterring bias judgement, supplier evaluation cultivates transparency and trust with suppliers.

Furthermore, routine supplier evaluation also ensures you continually review and re-evaluate suppliers’ performance so that only those consistently delivering value are retained on your approved vendor lists.

- Cost Optimisation

Cost optimisation focuses on achieving good value on goods and services purchased. While going with the lowest quotes received may be perceived as cost savings, it may not yield cost-effective or optimal outcomes. Suppliers offering lower prices may sometimes have to compromise on factors such as delivery times or product quality, which would impact your business operations.

With supplier evaluation, organisations can incorporate additional criteria to thoroughly assess suppliers, taking additional factors such as quality or experience into consideration. This improves the selection process to engage suppliers who are capable of delivering value while maintaining reasonable costs, and enhances cost optimisation efforts by prioritising overall value rather than just the initial cost.

- Risk Mitigation

Every relationship comes with some risk, and with supplier evaluation processes, organisations can better understand and evaluate the value and associated risks of potential suppliers.

Standardised evaluation offers evaluators a structured framework to accurately determine which vendors are most suitable for the job at hand. This approach enhances decision-making by providing consistent criteria for evaluating suppliers, ultimately leading to more informed and effective vendor selections.

- Improved Business Outcomes

Clear supplier management, combined with comprehensive evaluation guidelines, enables evaluators to better identify the most suitable suppliers for your organisation’s requirements. Supplier evaluation not only streamlines the vendor selection process but also mitigates bias, reduces corruption risks, and enhances compliance efforts. These practices result in nurturing productive working relationships with a well-matched set of suppliers, ultimately leading to improved business outcomes for your organisation.

Types of Supplier Evaluation

There are several methods to carry out supplier evaluation assessments, each with their own merits and challenges.

Below we share 3 methods of supplier evaluation:

1. Weighted Point Method

What is it: This is a quantitative approach to supplier evaluation, involving the scoring of suppliers based on criteria weighted according to their importance. The criteria commonly includes price, delivery timeline, compliance, ESG rating and more.

How is it performed: Once all proposals are received, the evaluator(s) receive the proposals together with a scorecard. They then assign points to each criteria for each supplier, and the total score is calculated by multiplying the given points by their corresponding weightage. The supplier with the highest score is deemed the most favourable option.

Pros: The weighted point method is clear, transparent and simple in its execution. All evaluators are given the same scorecard and the selected supplier is objectively chosen based on the total scores received.

Cons: However, this method may not capture all relevant considerations, such as the supplier relationship or reliability. Scorecards with qualitative criteria such as quality or customer service may also hinder objective evaluation.

2. Cost-Based Method

What is it: The cost-based method represents another quantitative approach to evaluation, assessing the total cost of engaging business with the supplier.

How is it performed: In such evaluations, a dollar amount is determined for all factors of the purchase, such as transportation cost, quality cost, opportunity cost, and potential hidden costs. From there, all these expenses are included into the assessment, and the supplier with the lowest cost is considered the most favourable option.

Pros: This method is likely to closely align with business objectives, offering companies a realistic expectation of the financial commitment from the supplier.

Cons: However, assessing the total cost can be complex and time-consuming, and it may not accurately evaluate non-financial factors.

3. Price-Quality Method

What is it: The Price-Quality Method, Price-Quality Matrix or PQM, combines both quantitative and qualitative evaluation, where companies evaluate both pricing and quality together to select the supplier that fits both evaluation criteria.

How is it performed: In such evaluations, price quotations and proposals may be submitted separately. Quotations are scored based on a scorecard with predetermined criteria for each score. Proposals are assessed and scored by evaluators with a predefined list of requirements. Both scores for each supplier are combined, and the supplier with the highest total score is considered the best option.

Pros: The PQM method offers a more comprehensive evaluation of suppliers by considering both cost and quality factors.

Cons: However, this can be a tedious and time-consuming process that may prolong purchasing cycles if evaluations are not performed timely. Ensuring compliance during the bid submission and evaluation stage may also require more manpower if performed manually.

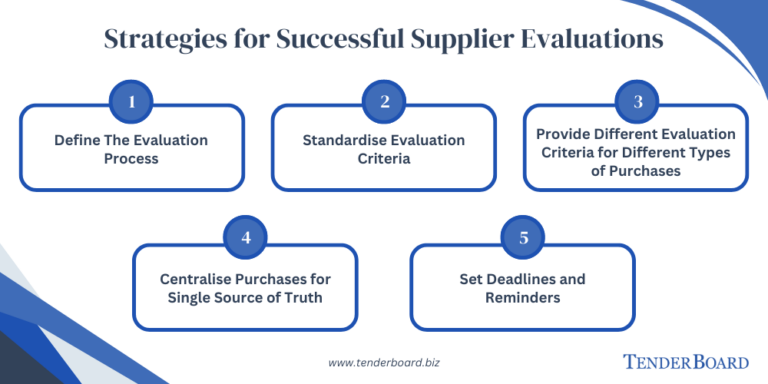

5 Tips for Successful Supplier Evaluation

Successful supplier evaluations are performed methodically and consistently. This ensures all stakeholders, including purchase requestors, evaluators and suppliers, are aware of the criteria required for a successful relationship.

Here are five strategies to help you implement successful supplier evaluations within your organisation:

1. Define the evaluation process

Clearly defining evaluation workflows provides transparency and clarity for staff. Evaluators know when they need to assess purchases, ensuring evaluations are conducted promptly and systematically. This clarity reduces confusion and ensures that all evaluations follow established guidelines.

2. Implement standardised evaluation criteria

Predetermined criteria encourages impartial evaluation, as all supplier bids are scored based on the same requirements. This consistency ensures that suppliers are assessed fairly and objectively.

3. Provide specific evaluation requirements for different types of purchases

Maintenance contractors and IT equipment suppliers should not be evaluated the same way. By tailoring evaluation criteria to meet the specific needs of different types of purchases, organisations can ensure evaluations are performed thoroughly and appropriately for the scale and complexity of the purchase. E.g. small value purchases could have a single evaluator, while million dollar purchases may include technical evaluators.

4. Centralise purchases for single source of truth

A central source for all purchasing information provides staff easy access to any relevant information required for evaluation. This minimises the time and effort needed to gather information from disparate sources, and reduces purchase workflow bottlenecks.

5. Provide a timeframe and set up reminders for evaluator

Setting deadlines and sending reminders helps to ensure that evaluations are conducted in a timely manner, reducing the risk of missed deadlines and potential disruptions to your procurement process.

Managing thorough supplier evaluations manually is often a tedious process, with more manpower required to ensure corporate governance and compliance. But your supplier evaluation processes shouldn’t be at the mercy of manual labour. Through digitalisation and automation of your procurement workflows, supplier evaluations can be more effective and streamlined than ever.

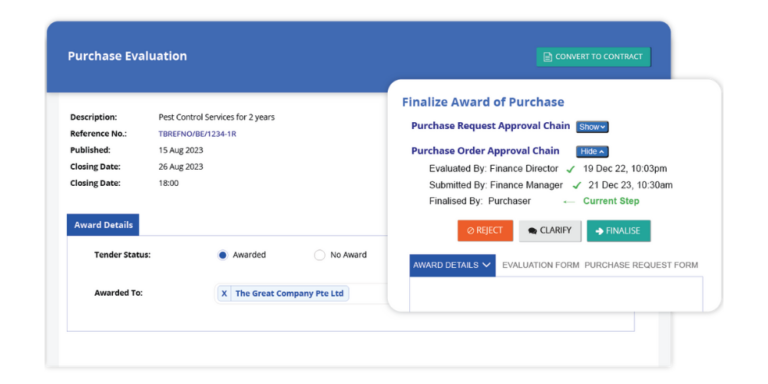

TenderBoard Supplier Evaluation Module

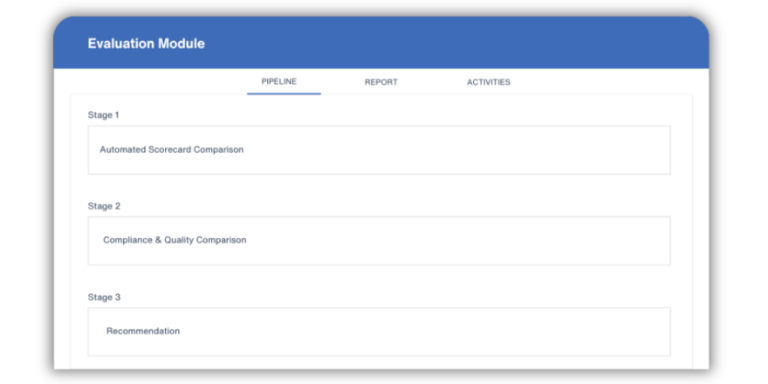

TenderBoard’s supplier evaluation module offers easy and seamless evaluation. With highly configurable fields and criteria, companies can pre-determine requirements for different types of purchases, allowing evaluators to perform qualitative and quantitative evaluation quickly and effectively.

Quantitative scoring can be configured into the system, automatically calculating the scores for each supplier bid. For qualitative evaluation, TenderBoard automatically sends out the evaluation criteria to evaluators, with reminders at predetermined intervals to ensure evaluations are completed timely.

Keen to learn how you can evaluate suppliers efficiently and effectively? Reach out to us today.